Transmission Utility Structures

To provide long life in the field, our transmission poles are crafted with corrosion-resistant galvanized steel. Our world-class manufacturing plant at the Indapur industrial estate, near Pune, features advanced galvanizing facilities and equipment. Our technical team provides uncommon expertise in surface treatments and galvanizing processes which deliver reliable performance.

With in-house engineering expertise, we are able to provide a high-level of design customization and flexibility. Various attachments are available to allow for tangent, angle or dead-end pole configurations.

Contact our representative to learn more about galvanized steel poles for power transmission, or send an inquiry to request information or a quote.

We offer high-quality galvanized-steel utility poles for power distribution which provide reliable support to power lines. Standard and custom designs are available.

Featuring a constant taper, steel power distribution poles provide consistently uniform diameters. Steel also provides uniform material strength throughout the entire structure, providing more consistent and predictable results and longer span lengths in comparison to conventional RSJ & PPC/PSC Poles.

Being an inherently ductile material, steel tends to bend rather than break, resulting in structural reliability and reducing the chance of catastrophic failure in the field.

Contact our representative to learn more about galvanized steel poles for power distribution, or send an inquiry to request information or a quote.

Building on a strong heritage of proven results, Valmont’s engineering expertise in designing a broad array of products for the energy/power industry is widely acknowledged.

We offer custom-designed and manufactured steel structural components which enable our customers to build power-generation utility substations.

Contact our representative to learn more about substation structural components, or send an inquiry to request information or a quote.

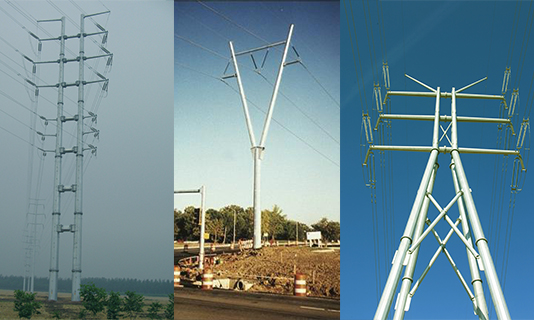

Sometimes standard products do not meet the power transmission needs of a particular customer or project. As such, Valmont also offers special structures.

These project-specific solutions are custom designed, fabricated and installed to ensure they completely meet a site’s specific requirements and specifications. Examples of these installations include our PyraMax, Y-Poles, and Double Poles.

These structures exemplify the technological experience and expertise Valmont offers, as well as our dedication to always delivering results to our customers.

HTLS conductors

ACCC Conductor

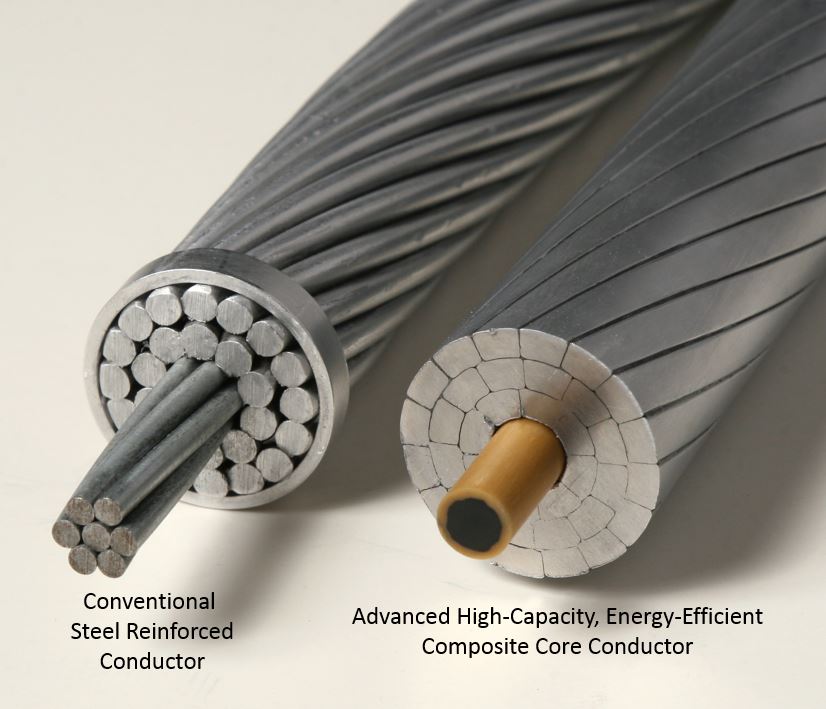

The CTC Global ACCC Conductor utilizes a hybrid carbon and glass fiber core embedded in a high-performance thermoset epoxy matrix. The central carbon fiber core consists of tens of thousands of high-strength, high-modulus unidirectional carbon fibers that are surrounded by a protective layer of glass fibers. The outer glass fibers improve toughness and flexibility while also providing a galvanic barrier to prevent corrosion with the conductive aluminum strands.

The ACCC Conductor hybrid core is not only twice as strong as steel, it is also 70% lighter.

The lighter weight allows the CTC Global ACCC Conductor – of any size – to utilize ~28% more aluminum without a weight or diameter penalty. The compact trapezoidal strands and smooth surface composite core work in unison to dissipate wind-induced vibration. While the aluminum strands are fully annealed, offering the highest degree of conductivity for any aluminum available today, the composite core offers a coefficient of thermal expansion about ten times less than steel.

The low coefficient of thermal expansion mitigates conductor sag under heavy electrical load conditions. While the composite core is fully elastic and will not plastically deform or yield like conventional conductor steel core strands, the overall modulus of the CTC Global ACCC Conductor core is lower than that of steel. The lower modulus allows the conductor to stretch degree during extreme ice and wind loading events. However, when the event subsides, the composite core fully returns to its pre-stressed condition allowing the aluminum strands to subsequently relax. This type of event further improves the conductor’s self-damping characteristics and reduces the conductor’s thermal knee-point to further reduce conductor sag under heavy electrical load conditions.

In some cases pre-tensioning can be performed during installation to achieve these added benefits. When heavy ice and wind load conditions are anticipated, CTC Global and its worldwide stranding partners also offer a higher-modulus version of the composite core known as ULS. ACCC ULS Conductors are also frequently used on long spans.

ACCC ULS Conductor

First deployed on a 1.4 kilometer lake crossing in Africa in 2013, The ACCC® ULS Conductor offers greater strength, a lower coefficient of thermal expansion and higher modulus of elasticity than the standard ACCC® Conductor core. The ULS version has a higher carbon fiber content raising the tensile strength from 310 to 375 ksi. While the added strength can enable longer spans, the higher modulus and increased stiffness reduce sag and blow out during high wind conditions. Improved stiffness can also reduce sag under heavy ice load conditions.

The higher carbon fiber content also reduces the coefficient of thermal expansion from 1.6 x 10-6 /°C to 0.75 x 10-6 /°C.

While dozens of engineers have specified ACCC® ULS Conductor for projects, worldwide, the ULS version of the ACCC® Conductor has served our clients well. The ACCC® ULS Conductor is available in many sizes and offers designers added design flexibility.

The ACCC® ULS Conductor can be ordered with Type 1350-O fully annealed aluminum or as an AZR version with Aluminum-Zirconium thermal resistant alloy for even higher overall conductor strength.

ACCC AZR Conductor –

Expanding the capabilities of the ACCC® Conductor using aluminum zirconium alloy

ACCC® AZR Conductor uses either the standard 310 ksi core or the higher strength 375 ksi core that is then wrapped with one or more layers of a high strength, thermal resistant aluminum-zirconium alloy. While conventional ACCC® Conductors typically use fully annealed aluminum to maximize conductivity, the ACCC® AZR Conductor offers nearly the same efficiency, but far greater overall strength. The added strength and increased tensile modulus mitigates conductor sag under heavy wind or ice loads, or very long spans.

ACCC InfoCore System

The ACCC InfoCore® System reduces real-world conductor installation risk experienced by utilities, contractors and lineman across the globe. These dedicated professionals know that even with the best tools, equipment and field conditions, accidents can happen. By using a proprietary infrared light system, special fibers in the core, and a robust data-capture and recording methodology, the ACCC InfoCore® System can confirm the integrity of the conductor in minutes. While not mandatory for every installation, this capability serves to improve reliability and confidence. The system is capable of confirming very long continuous spans and is currently being utilized globally.

How it Works

The process begins by accessing the conductor at each end, prepping the core ends using tools provided in the ACCC InfoCore® Confirmation Kit.

- Transmitter is attached to one end of the ACCC® Conductor.

- Receiver is attached to the other end.

- Controller receives, reviews and records the results.

- Core prep generally takes less than five minutes and the receiver confirms a successful installation in seconds.

CTC Global’s ACCC InfoCore® System makes confirming successful conductor installation safe, simple and fast. Alternate methods include CT Scan, X-ray inspection, and magnetic pulse technology but these devices are very slow and expensive.

ACCC Composite Core

CTC Global’s ACCC® Composite Core consists of high-strength carbon and glass fibers embedded in a toughened thermoset epoxy resin matrix. The composite core is manufactured to aerospace quality specifications using a continuous pultrusion process developed by highly skilled pultrusion experts.

The ACCC® Conductor’s composite core offers a strength to weight ratio approximately six times better than steel, with a coefficient of thermal expansion about ten times lower. The composite core is also impervious to corrosion and cyclic load fatigue.

CTC Global’s ACCC® Conductor cores are currently available in 310 and 375 ksi tensile strengths. The higher strength version – referred to as ULS – also offers a higher modulus to accommodate longer spans and extreme ice loads. For comparison, extra high strength steel is rated at 285 ksi, but is approximately 70 percent heavier than the ACCC® Composite Core.

ACCC Hardware

CTC Global ACCC® Hardware uses high-strength, high-performance hardware components that offer fast, straight forward installation techniques that offer superior performance and longevity compared to conventional systems. CTC Global’s ACCC® dead-ends and splices have been installed at over 1,000 project sites in more than 60 countries and have provided flawless performance without a single failure. Installations have ranged to sub-transmission voltage installations to EHV multi-bundled installations.

CTC Global ACCC® Hardware Projects

CTC Global ACCC® Conductor projects have included ocean crossings, river crossings, highly corrosive industrial areas, heavy ice zones, mountain and desert crossings. CTC Global manufactures internal hardware components (stainless steel) at its manufacturing center in Irvine, California. CTC Global internal components are then delivered to several manufacturing partners worldwide, Our manufacturing partners add additional components such as aluminum sleeves, jumper pads, oxidation inhibitor and other pieces and deliver complete hardware packages to our valuable customers, worldwide.

Beginning in 2003, CTC Global hardware components and completed systems have been thoroughly tested at several international laboratories following ASTM, IEC and other relevant standards. These tests include stress-strain testing, high-temperature cyclic and sustained load tests, short circuit tests and many others.

All hardware components and manufacturing partners are certified to the latest ISO standards.

ACCC® Conductor Installation Overview

Quality Assurance

Quality you can depend on is a hugely important factor in our business. That’s why CTC Global ACCC® Conductor is produced with the highest quality standards throughout the manufacturing process. We’ve integrated quality assurance into every operation, and our Irvine, California operations are certified to ISO 9001:2015 standards by NSF International Strategic Registrations.

CTC Global manufactures all ACCC Products with complete traceability of material components, and every item is fully tested prior to leaving the factory. We ship every reel of completed composite core with a Certified Test Report that itemizes all the tests successfully completed and provides lot traceability.

All of our stranding sources are rigorously audited by our Quality Assurance organization, and must comply with ISO 9001:2015 standards. In order to be part of our supply chain, all stranding sources must gain a successful Quality Assurance audit report, and pass rigorous stranded conductor testing by both CTC Global and independent laboratories.

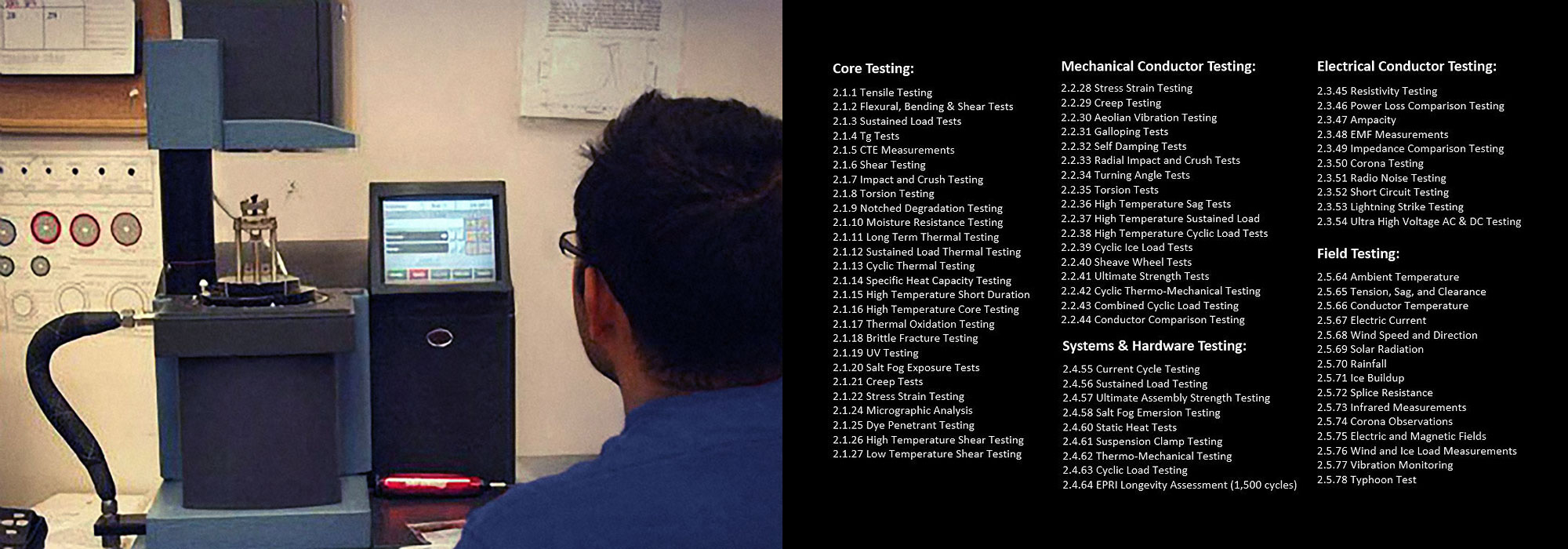

Testing ACCC Conductor

Testing ACCC® Conductor, its composite core and ancillary hardware components began in 2003 and continues to this day. The magnitude of the testing is remarkable and the results outstanding. Initial testing was undertaken to ensure performance targets were met and enable CTC Global to share the results with customers. Industry standard test protocols were also completed to assess overall conductor and hardware performance. Additional test protocols were developed to provide further insight into performance and longevity

Examples include work done by EPRI and EDF in collaboration to better understand the properties of composite materials. American Electric Power – who now have over 5,000 km of CTC Global ACCC® Conductor in service also developed a Sequential Mechanical Test to assess ACCC® Conductor and compare it to other conductors. A number of universities and international laboratories continue to explore the limits of composite materials which is helping CTC Global raise the performance bar even higher.

How ACCC Conductor Compares

ACCC Conductor operates cooler, improves efficiency

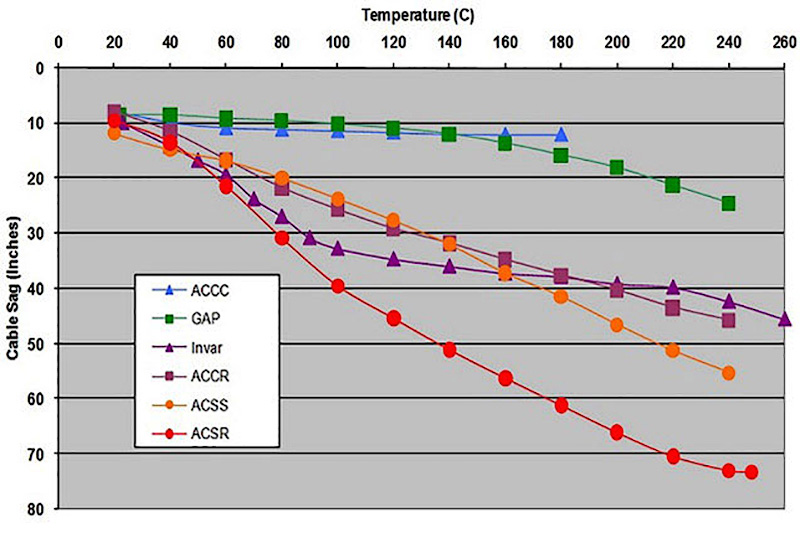

In the past, T&D designers had few choices. All aluminum conductors such as AAC and steel reinforced conductors such as ACSR. In the 1970’s and 1980’s new conductors were introduced that could be operated at higher temperatures (to carry more current) such as ACSS. Additionally, Gap type conductor and Invar steel conductors were also introduced. While Gap conductor is a bit difficult to install and Invar conductors exhibit very high magnetic hysterisis losses, new composite core conductors were subsequently introduced in the early 2000’s. These included 3M’s ACCR conductor which replaced the conventional steel core strands with ceramic fiber reinforced aluminum strands and the CTC Global ACCC® Conductor which uses a single carbon and glass fiber (hybrid) core embedded in a high-temperature thermoset resin matrix to optimize performance and improve efficiency.

To assess the differences between different conductor types, Ontario Hydro in Canada performed a test at Kinectrics Lab. The test subjected the different conductors (Drake size equivalents) to 1,600 amps on a 65 meter (215 foot) test span. While the primary objective of the test was to compare conductor sag, the temperatures that each conductor reached under the 1,600 amp load also provided great insight in terms of each conductor’s efficiency. Notice in the graph below the differences in sag. Notice also how much cooler the ACCC® Conductor operated under the same load condition. Cooler operating temperatures (from 60 to 80 degrees C) reflect a substantial improvement in efficiency. While many other manufacturers are beginning to recognize the advantages of the ACCC® Conductor and its hybrid carbon fiber core, CTC Global’s expertise in composites and substantial field experience are unrivaled. If you are considering a high-performance economic solution, look no further. CTC Global offers performance and price advantages others can’t touch.

While dozens of engineers have specified ACCC® ULS Conductor for projects, worldwide, the ULS version of the ACCC® Conductor has served our clients well. The ACCC® ULS Conductor is available in many sizes and offers designers added design flexibility.

The ACCC® ULS Conductor can be ordered with Type 1350-O fully annealed aluminum or as an AZR version with Aluminum-Zirconium thermal resistant alloy for even higher overall conductor strength.

SOLUTIONS

Conductor efficiency can substantially reduce CO2 emissions

In the world of commodity transmission conductors, conductor efficiency is generally not considered to be high on the priority list. Conductor selection is generally based on load considerations. But times are changing. Looking back a few years, consider the substantial investments that were made to improve the efficiency of generators to reduce fuel consumption and/or help improve the economic viability of competing generation technologies such as solar and wind. Improved transformer technologies, while slightly more expensive, were also easy to justify – as they offered reduced lifecycle costs and improved efficiency.

On the demand side, consider that billions of dollars have been spent to improve the efficiency of demand side appliances such as refrigerators, air conditioning units and even light bulbs. In many cases regulators and power companies subsidized the purchases of these appliances to reduce stress on the grid and postpone the need to build new generation, which is generally a challenging and expensive proposition.

On the conductor side, very little consideration historically has been given to conductor efficiency and line losses as these costs are generally passed through to the consumer. But, more recently, as industry experts and policy makers begin to recognizing the impact climate change is having on transmission and distribution assets and the environment, more consideration is being given to improving efficiency even further. Conductor efficiency is now being considered as well.

To put this in perspective, consider a 100 mile section of recently completed 345 kV line upgrade in the United States. CTC Global ACCC® Drake size conductor (double bundled) was used to replace Drake size ACSR to increase line capacity. Based on ambient weather conditions and other operating assumptions at a 62% load factor, IEEE 738 calculations suggest the ACCC® Conductor would save over 300,000 MWh of electricity per year on the 100 mile line.

As a basis for comparison, let’s consider the energy savings offered by a 100 watt equivalent LED light bulb replacement. The LED reduces electrical consumption by around 80% compared to a standard incandescent light bulb. Translated, the use of 12.5 LED bulbs would save 1 kWh of electricity per hour. 12,500 LED bulbs would, therefore, save 1 MWh. If we assume a 4 hour per day / 365 day per year light bulb utilization, it would take 2,568,493 LED bulbs to save 300,000 MWh of electricity. At a cost of $20 per LED bulb, the energy savings would translate into a capital cost of $51,369,863. The CTC Global ACCC Conductor (3 phase, double bundled), on the other hand, would cost roughly $14,000,000 for 600 total miles of wire (not including hardware and installation costs). While these and other project costs would certainly add substantially to this figure, it would be safe to assume that the conductor would not have to be replaced every few years like the light bulbs. If the LEDs had to be replaced once every five years, the cost of the energy savings would climb to well over $400,000,000. From an environmental perspective, based on the average CO2 emissions from all combined sources of electricity in the state where this project was completed, either investment choice would reduce emissions by approximately 200,000 metric tons of CO2 per year.

Considering that the average car in North America emits 4.75 metric tons of CO2 per year, this would be the equivalent of taking 42,000 cars off the road for every one-hundred circuit miles of 345 kV conductor upgraded or every 2.5 million lightbulbs replaced. It appears that conductor replacement may be a significantly less expensive alternative. Conductor efficiency does matter and CTC Global ACCC is the conductor of choice.

Increase capacity with ACCC® Conductor

CTC Global’s ACCC® Conductor was developed to increase capacity and carry twice the current of conventional all-aluminum and steel reinforced conductors. While classic AAC, AAAC and ACSR conductors were limited to operating temperatures of ~90°C, other high temperature conductors such as ACSS, Invar and GAP were also designed to carry twice the current as well. The capacity advantages CTC Global’s ACCC Conductor offers over the alternatives is based on CTC Global’s patented composite core which has a coefficient of thermal expansion about 90% lower than steel core strands. So while other high-temperature conductors can operate at higher temperatures while carrying more current, CTC Global’s high-capacity ACCC Conductor mitigates thermal sag. This makes it an outstanding choice for increasing the capacity of existing transmission and sub-transmission lines without the need to replace or reinforce existing structures.

Added line capacity offers several advantages. The ability to use CTC Global’s ACCC® Conductor can, in some cases, mitigate the need to build additional transmission lines. Added capacity can also reduce grid congestion. Grid congestion can substantially drive up wholesale and retail electrical costs and prevent access to the cleanest source of generation. The added capacity offered by CTC Global’s ACCC Conductor can also improve grid reliability and prevent very costly power outages. For instance, should an adjacent power line go out of service for planned or unplanned reasons, CTC Global’s ACCC Conductor can handle the extra load to make sure that the power needed is delivered.

As climate change continues to increase the frequency and severity of weather related events, the added capacity offered by CTC Global’s ACCC Conductor is more important than ever to prevent outages and the extreme economic impact. Delivering clean, efficient, affordable and reliable energy is what drove CTC Global to develop, test and commercialize the ACCC Conductor. Without it, we can’t pump water to grow crops, manufacture products to compete in a growing global economy or improve the quality of life for millions of people. When you need added capacity, think ACCC Conductor.

Reliability

There is nothing more important to grid operators than reliability. It is absolutely key and conductor performance is mission critical. Sagging lines can cause sag trip outages, economically devastating blackouts, and jeopardize human life and property. The CTC Global’s ACCC® Conductor offers a new level of performance and unprecedented reliability. Longevity is also important. The ACCC Conductor’s composite core raises this performance bar as well. The ACCC Conductor’s hybrid carbon fiber core is not only resistant to harsh environmental conditions and corrosion, it also resists cyclic load fatigue. In the world of conductors everything is cyclic including tension, temperature, vibration and stress. These are just a few reasons why carbon fiber composite materials are finding their way into other highly demanding applications. Boeing, for instance, designed the 787 Dreamliner using carbon fiber technology not only to improve efficiency and performance, but also to extend the airframe’s service life as carbon fiber is highly resistant to cyclic load fatigue.

In 2003, following a series of events that included inaccurate telemetry data, computer glitches and reboot failures the electric power grid in the northeast United States and Canada experienced a widespread blackout caused by a series of conductor sag-trip outages. CTC Global’s ACCC Conductor would have certainly prevented or substantially minimized this event as CTC Global’s high-capacity, low-sag ACCC Conductor does not sag under extremely heavily loaded conditions. The ability of CTC Global’s ACCC Conductor to carry twice the current (or more) compared to conventional steel reinforced conductors is well suited to improving grid reliability – especially during periods of high electrical demand and during weather event conditions.

When improving grid reliability is your challenge, look no further than CTC Global’s ACCC Conductor. It offers improved reliability and much, much more.

Resiliency

Following Super Storms Katrina, Sandy, Haiyan and many others it has become readily apparent that climate change is causing the frequency and severity of weather related events to take increasingly heavier tolls on our power grids. A substantial effort has begun not only to harden the grid to make it more resistant to damage, but also to leverage modern technologies to make inevitable damage easier and faster to repair. Climate change has also increased fire hazards in certain areas. CTC Global’s ACCC® Conductor has a proven track record of not only resisting damage from severe weather conditions, but also surviving when wood and metal structures were burned down or knocked to the ground.

While CTC Global’s ACCC Conductor’s composite core is twice as strong as steel (up to 375 ksi) which can prevent or minimize damage to both the conductor and adjacent structures (broken power lines can create unbalanced mechanical loads on structures causing failures), CTC Global’s ACCC Conductor has demonstrated itself time and time again to resist damage and improve grid resiliency.

For example, when an EF4/EF5 tornado struck Moore, Oklahoma flying debris hit a 125 foot tall steel monopole supporting CTC Global’s ACCC Conductor. The pole was knocked over by 45 degrees and didn’t hit the ground. Though the shock wave snapped the ACCC Conductor’s aluminum strands, CTC Global’s composite core did not break. Linemen in two bucket trucks were able to simply splice in 20 feet of new ACCC Conductor to repair the damage. If the conductor had snapped completely it would have taken much longer to make the repair and get the line back in service.

The year before, in Nevada, wood H-frame structures supporting CTC Global’s ACCC Conductor were burned to the ground during a wild fire. Remarkably the ACCC Conductor was not damaged. After the wood structures were replaced, the ACCC Conductor was lifted back into position and put back in to service.

Achieve emission reduction goals with CTC Global’s high-efficiency ACCC® Conductors

Concerns about climate change continue to shape corporate and regulatory policy. The use of high-capacity, high-efficiency ACCC® Conductors can help you cost-effectively achieve your organization’s emission reduction goals

CTC Global’s high-capacity, high-efficiency ACCC® Conductors offers one of the most cost-effective means of reducing fuel consumption and associated emissions, while also increasing grid capacity to support the deployment of more clean renewable energy.

Let’s consider an example based on a recently completed American Electric Power project in Texas. Looking at a 100 mile section of 345 kV line designed to carry 3,000 amps with a load factor of 62%, the use of CTC Global’s Drake size (double bundled) ACCC Conductor would reduce line losses by 30% compared to an equally sized ACSR Drake conductor. This translates into a savings of 300,000 MWh per year.

For comparison, consider the energy savings offered by a 100 watt equivalent LED light bulb replacement. The LED light bulb reduces electrical consumption by around 80% compared to a standard incandescent light bulb. Translated, the use of 12.5 LED bulbs would save 1 kWh of electricity per hour. 12,500 LED bulbs would therefore save 1 MWh. If we assume a 4 hour per day / 365 day per year light bulb utilization, it would take 2,568,493 LED bulbs to save 300,000 MWh of electricity. At a cost of $20 per LED bulb, the energy savings would translate into a capital cost of $51,369,863.

CTC Global’s high-efficiency ACCC Conductors, on the other hand, would cost roughly $14,000,000 (not including hardware and installation costs). While these and other project costs would certainly add substantially to this figure, it would be safe to assume that the ACCC Conductor would not have to be replaced every few years like the light bulbs. If the LED light bulbs had to be replaced once every five years, the cost of the energy savings would climb well over $400,000,000.

From an environmental perspective, based on the average CO2 emissions from all combined sources of electricity in the state where this project was completed (Texas), either investment choice would reduce emissions by approximately 200,000 metric tons of CO2 per year. Considering that the average car in North America emits 4.75 metric tons of CO2 per year, this would be the equivalent of taking 42,000 cars off the road for every one-hundred circuit miles of 345 kV conductor upgraded or every 2.5 million lightbulbs replaced. CTC Global’s high-efficiency ACCC Conductors offers a significantly less expensive alternative.

- The use of ACCC Conductors can reduce GHG emissions and fuel / operating costs for natural gas, oil and coal-fired generation units.

- The use of ACCC Conductors can enable the efficient delivery of more electricity to accommodate growing fleets of electric cars and space heaters.

- The use of ACCC Conductors can alleviate grid congestion to allow more access to lower cost and cleaner sources of energy.

- The use of ACCC Conductors can increase the number of Renewable Energy Credits (RECs) you receive for your renewable resources by delivering more power with reduced line losses.

- The use of ACCC Conductors can reduce GHG emissions at potentially lower costs compared to other solutions such as scrubbers, carbon capture technologies and – surprisingly – even incandescent light bulb replacement.

ACCC Hardware

CTC Global ACCC® Hardware uses high-strength, high-performance hardware components that offer fast, straight forward installation techniques that offer superior performance and longevity compared to conventional systems. CTC Global’s ACCC® dead-ends and splices have been installed at over 1,000 project sites in more than 60 countries and have provided flawless performance without a single failure. Installations have ranged to sub-transmission voltage installations to EHV multi-bundled installations.

CTC Global ACCC® Hardware Projects

CTC Global ACCC® Conductor projects have included ocean crossings, river crossings, highly corrosive industrial areas, heavy ice zones, mountain and desert crossings. CTC Global manufactures internal hardware components (stainless steel) at its manufacturing center in Irvine, California. CTC Global internal components are then delivered to several manufacturing partners worldwide, Our manufacturing partners add additional components such as aluminum sleeves, jumper pads, oxidation inhibitor and other pieces and deliver complete hardware packages to our valuable customers, worldwide.

Beginning in 2003, CTC Global hardware components and completed systems have been thoroughly tested at several international laboratories following ASTM, IEC and other relevant standards. These tests include stress-strain testing, high-temperature cyclic and sustained load tests, short circuit tests and many others.

All hardware components and manufacturing partners are certified to the latest ISO standards.

ACCC® Conductor Installation Overview

Quality Assurance

Quality you can depend on is a hugely important factor in our business. That’s why CTC Global ACCC® Conductor is produced with the highest quality standards throughout the manufacturing process. We’ve integrated quality assurance into every operation, and our Irvine, California operations are certified to ISO 9001:2015 standards by NSF International Strategic Registrations.

CTC Global manufactures all ACCC Products with complete traceability of material components, and every item is fully tested prior to leaving the factory. We ship every reel of completed composite core with a Certified Test Report that itemizes all the tests successfully completed and provides lot traceability.

All of our stranding sources are rigorously audited by our Quality Assurance organization, and must comply with ISO 9001:2015 standards. In order to be part of our supply chain, all stranding sources must gain a successful Quality Assurance audit report, and pass rigorous stranded conductor testing by both CTC Global and independent laboratories.